How Much Does SLS 3D Printing Cost? Low Volume Pricing Insights

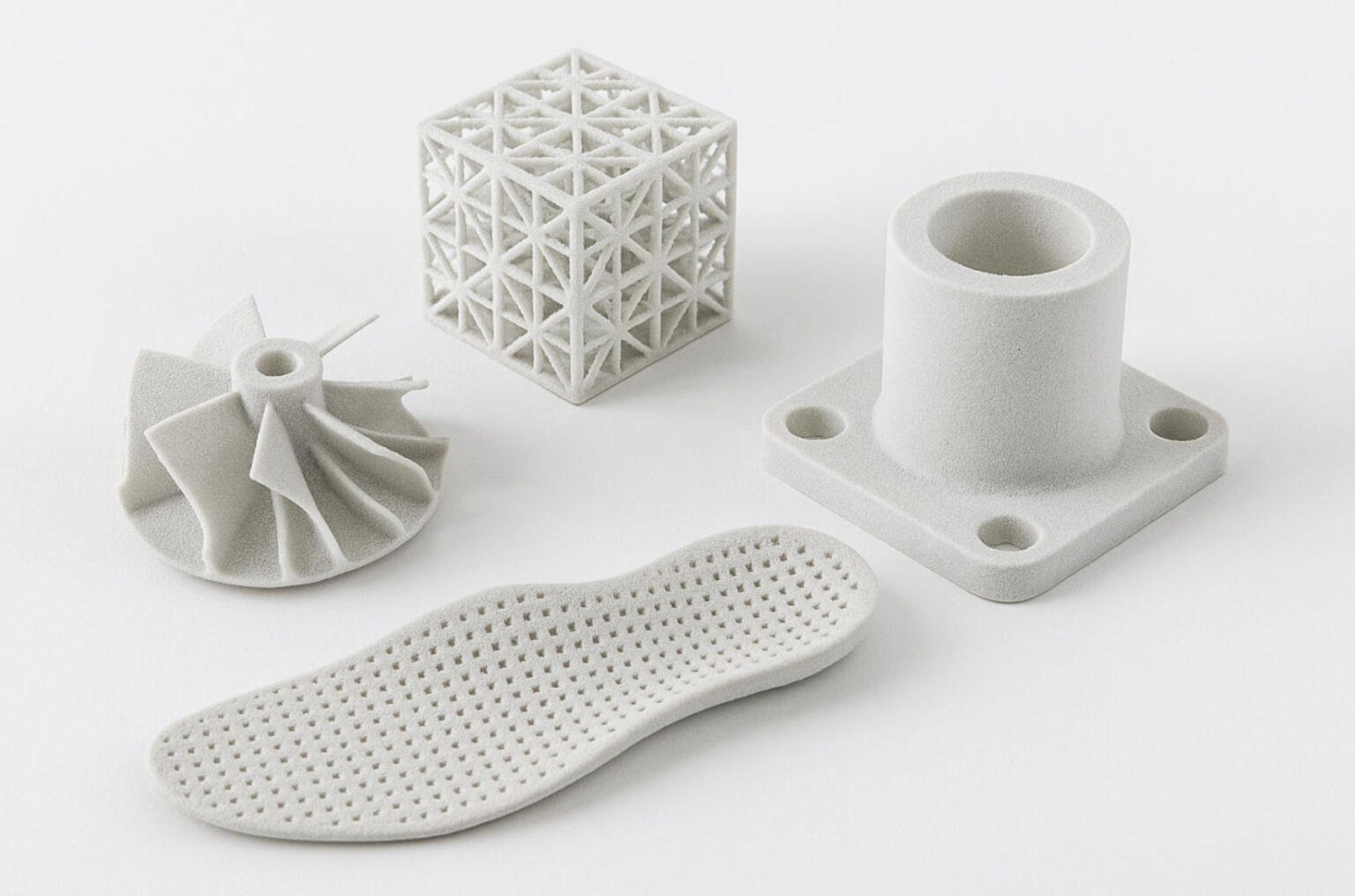

Selective Laser Sintering (SLS) is one of the most versatile 3D printing technologies, widely used for prototypes, functional parts, and low-volume production runs. However, one of the most common questions customers ask is: How much does SLS 3D printing cost?

The answer depends on several factors, including material type, part volume, complexity, finishing requirements, and production scale. In this article, we’ll break down the cost drivers and give you insights into what to expect when budgeting for low-volume SLS projects.

Key Factors That Influence SLS 3D Printing Costs

1. Material Selection

Different SLS materials come with different price points:

- PA12 (Nylon 12):The most common and cost-effective option, offering strength and durability.

- PA11:Biocompatible and flexible, slightly more expensive.

- TPU (Thermoplastic Polyurethane):Elastic material for flexible parts, often priced higher.

- Carbon Fiber Reinforced Nylon:Stronger and stiffer, suitable for engineering parts but at a premium.

- PP (Polypropylene):Lightweight and chemical-resistant, usually mid-range in cost.

Learn more SLS 3D Printing materials and selection guide>>

2. Part Volume and Quantity

Unlike CNC machining or injection molding, SLS pricing is not heavily influenced by setup costs. Instead, it depends on how much space your parts occupy in the build chamber. Larger parts or a higher number of parts will directly increase costs.

3. Geometry and Complexity

One of the advantages of SLS is the ability to print complex geometries without support structures. However, parts with intricate features or thin walls may require additional quality checks or reinforcement, which can impact cost slightly.

4. Post-Processing and Finishing

Base SLS parts have a slightly rough, grainy surface. Optional finishing steps add value but also increase costs:

- Bead blasting:Standard surface smoothing, usually included.

- Dyeing or coloring:Adds cost depending on color requirements.

- Vaporfuse smoothing:Premium option for a smooth, sealed surface (ideal for consumer products).

- CNC finishing or coating:For high-end applications.

5. Production Scale

SLS becomes highly cost-effective for low-volume production (dozens to hundreds of parts). Since there are no molds required, the cost per part drops significantly compared to injection molding for small batches.

Typical Price Ranges for Low-Volume SLS Projects

While prices vary depending on suppliers and requirements, here are some ballpark figures:

- Small parts (5–10 cm, PA12):$2–$20 per part in small batches.

- Medium parts (10–20 cm):$20–$100 per part.

- Large parts (20+ cm):$100+ depending on volume and finishing.

- Batch production (50–200 parts):Per-unit costs can drop by 10–30% compared to one-off pieces.

For example, producing 50 PA12 housings may cost significantly less per unit than producing just one or two, making SLS ideal for pilot production or bridge manufacturing.

Cost Comparison: SLS vs. Other Methods

- Injection Molding:Cheaper per part at high volumes but requires expensive tooling. For low volumes, SLS is usually more cost-effective.

- FDM 3D Printing:Cheaper for very simple prototypes, but lacks the mechanical strength and surface quality of SLS.

- CNC Machining:Excellent precision, but costs rise quickly with complex geometries compared to SLS.

How IN3DTEC Helps You Optimize Costs

At IN3DTEC, we provide on-demand SLS 3D printing services with cost transparency through our online quotation system. Our platform allows you to:

- Upload CAD files for instant pricing.

- Choose from a wide range of SLS materials (PA12, PA11, TPU, Carbon Fiber Nylon, PP, etc.).

- Select finishing options tailored to your project.

- Scale from one-off prototypesto hundreds of parts without the cost of tooling.

With a maximum build size of 620 × 320 × 320 mm, we can handle both small intricate parts and large functional components.

Final Thoughts

SLS 3D printing offers a unique balance of cost efficiency, material flexibility, and production scalability, especially for low-volume runs. While costs depend on material, geometry, and finishing, the technology remains one of the most competitive options for functional prototypes and bridge manufacturing.

Ready to see how much your parts will cost?

Upload your design today to IN3DTEC’s instant quoting platform and get a transparent price breakdown for your SLS project.