Industrial FDM 3D Printing Fast, Cost-Effective, Reliable

From prototypes to low-volume production, designed to meet industrial and creative needs.

What is FDM 3D Printing?

FDM (Fused Deposition Modeling) is an additive manufacturing technology that builds parts layer by layer using melted thermoplastic materials

- Low cost, ideal for rapid prototyping & Small Volume runs

- Supports a variety of engineering-grade plastics

- Can create medium-complexity structures

- Fast delivery, flexible for small-volume production

3D Printing Materials

We offer over 100+ 3D Printing materials and a wide range of surface finishes, and we also support customized materials for special projects

Surface Finishes For 3D Prints

Improve durability and performance with a selection of finishes

Anodizing

Polishing

Tumbling

Brushing + Electroplating

Smooth machining

Electroplating

Screen/logo Printing

Sandblasting/Shot Peening

Part marking/Laser engraving

Color Matching/Painting

Heat treatment

Insert, Thread Tapping

Vaporfuse Smoothing

Why IN3DTEC For Your 3D Printing

From idea to production, we help you get there faster.

300+ Industrial Printers

– Bigrep, Bambu, INTAMSYS, Stratasys, HP, Farsoon, BLT & more.

All Major Technologies

– FDM, SLA, SLS, MJF, SLM, PolyJet, MBJ, Ceramic, Sand Print & Metal Casting

Broad Material Options

– 100+ Plastics, metals, composites, and custom materials.

Fast Turnaround

– Speed without compromising quality.

Fast Turnaround

– Speed without compromising quality.

Expert Support

– Design optimization & engineering guidance.u

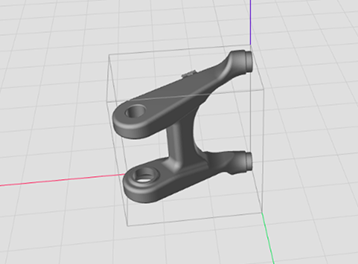

Walls are to thin, minimum recommended thickness value is 1.0

Show thin walls

From Quote To Delivery

Everything You Need In One Easy-to-use Platform

Our AI-powered online quoting tool delivers prices within seconds and makes order tracking and management effortless. With built-in DFM capabilities, it helps identify design errors early, saving you time and ensuring smoother part production.

No Minimum Quantity | AI-Powered DFM Analysis |Online Order Management | Flexible Lead Time & Shipping Options

“IN3DTEC is a wholly trusted partner. They help us develop new products more efficiently and quickly. High-quality products and competitive prices are also why we recommend them to more people.” Luis Ford at Leica Medical Product Design Team

Excellent 4.9 out of 5

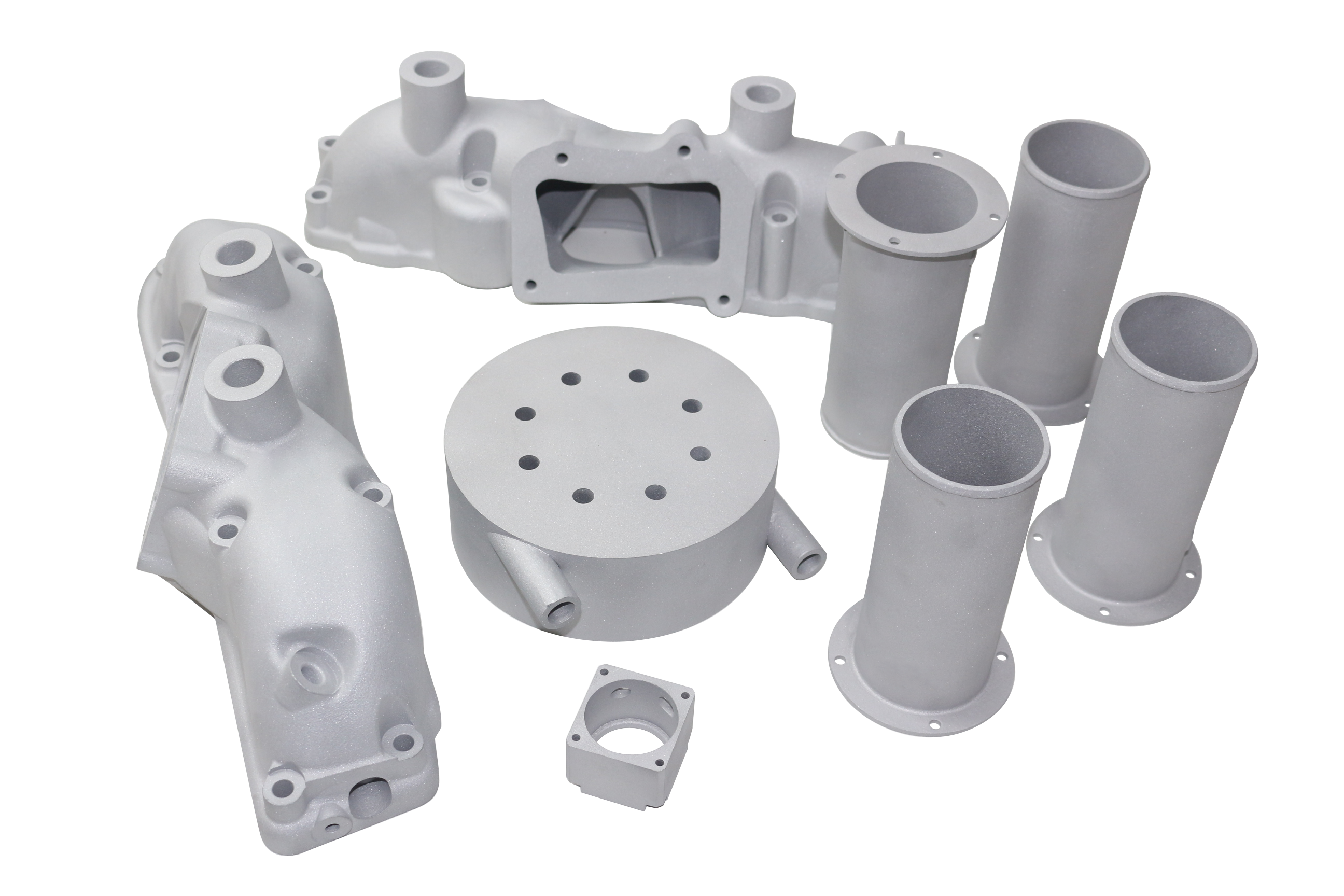

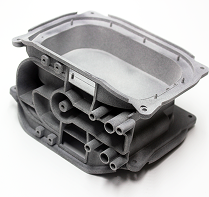

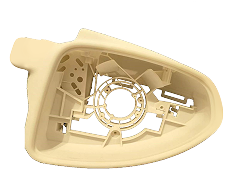

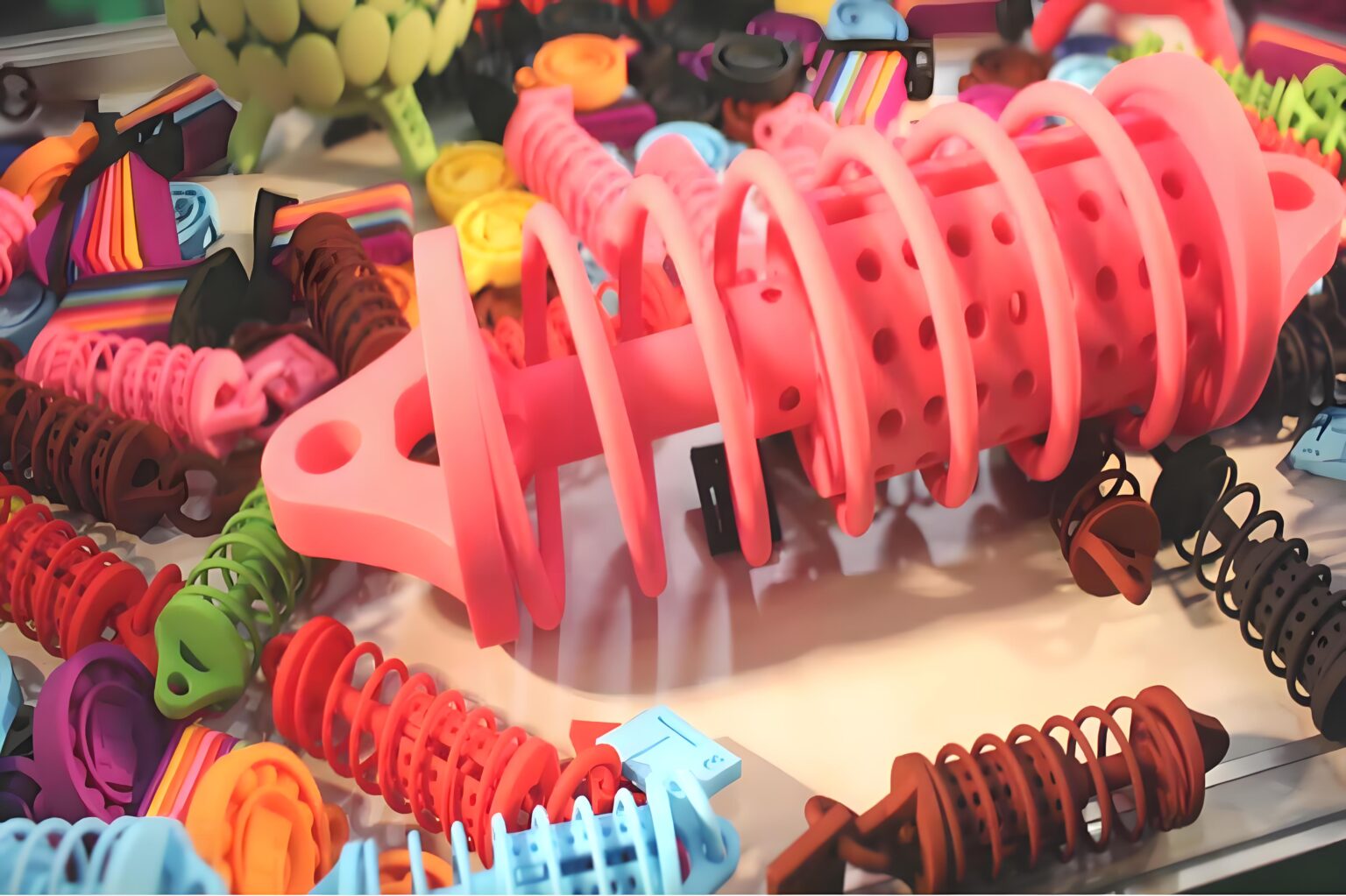

Gallery Of 3D Prints

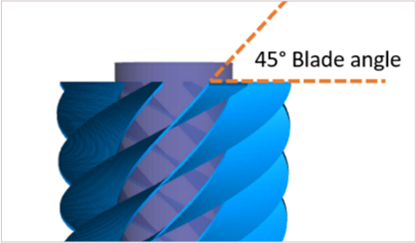

How Does FDM 3D Printing Works

The process uses a digital design that is uploaded to the 3D printer. There are a lot of different polymers used, such as ABS, ASA, PETG, PETG+CF, PC, Flame retardant, PA+CF, PEI, PPSF, and PEEK.

These take the shape of plastic threads that are fed from a coil and through a nozzle. The filaments are melted and fed onto the base, known as a build platform, both of the plate ad nozzle which are controlled by a computer. The computer works by translating the object and its dimension into co-ordinates that make it possible for the nozzle and base to follow.

Download The 3D Printing Guide

Discover proven design rules that help engineers and creators improve performance, save costs, and ensure consistent success in 3D printing projects.

How to Work With

Simply upload your CAD files.

Get real-time pricing and DFM insights within seconds. Or ask for manual design help.

Once your order is placed, we’ll begin production right away, and you can track and manage it anytime from your dashboard.

Partnering with FedEx, DHL, and UPS, we deliver your parts fast and on time, worldwide.

Put your Parts into Production Now

Q & A

A: Typically 15–25 copies, depending on geometry and resin type.

A: Low cost, fast turnaround, excellent surface quality, and suitability for small-batch production.

A: Automotive, consumer electronics, medical devices, robotics, and industrial design prototyping.

A: Typically ±0.3 mm / 100 mm(Min. +/-0.3mm), depending on size and geometry.

A: Yes, both tinted and fully transparent finishes are available, with painting or polishing if needed.

A: Polyurethane resins simulating ABS, PP, PC, PMMA, Rubber (shore A 30–95), and transparent materials.