SLA 3D Printing — High-Resolution Prototyping and Functional Parts

Achieve smooth surfaces, intricate details, and excellent accuracy with stereolithography. Perfect for prototypes, models, and end-use components.

What is SLA 3D Printing?

Stereolithography (SLA) is a resin-based 3D printing process that uses an ultraviolet laser to cure liquid photopolymer layer by layer. It is one of the most accurate and versatile additive manufacturing technologies, capable of producing highly detailed prototypes and functional parts with excellent surface finishes.

High-resolution printing for fine details and smooth surfaces

Excellent dimensional accuracy and tight tolerances

Wide range of functional and aesthetic resin materials

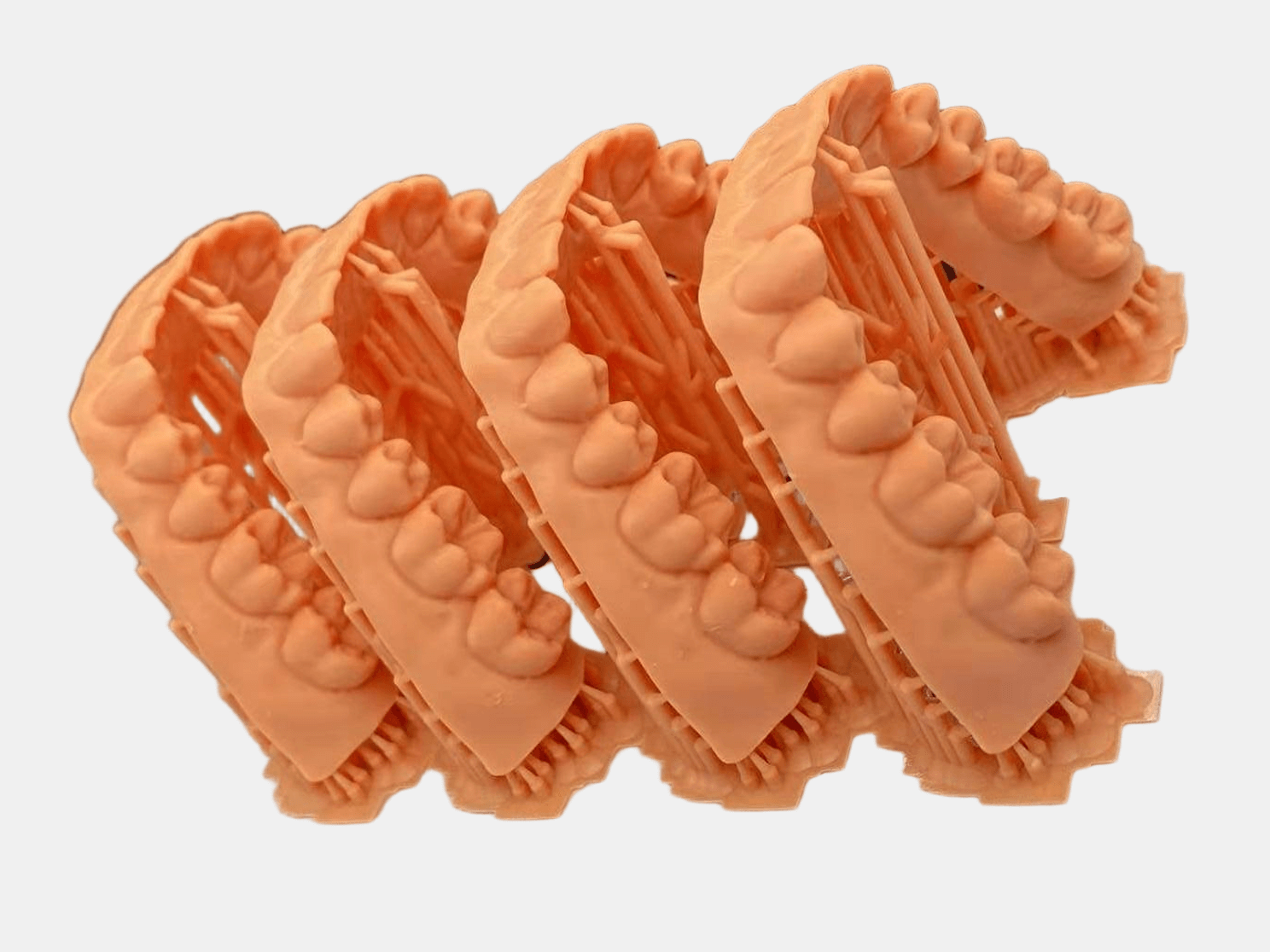

Ideal for prototypes, dental models, and end-use parts

Short lead times for low-volume production

3D Printing Materials

We offer over 100+ 3D Printing materials and a wide range of surface finishes, and we also support customized materials for special projects

Surface Finishes For 3D Prints

Improve durability and performance with a selection of finishes

Anodizing

Polishing

Tumbling

Brushing + Electroplating

Smooth machining

Electroplating

Screen/logo Printing

Sandblasting/Shot Peening

Part marking/Laser engraving

Color Matching/Painting

Heat treatment

Insert, Thread Tapping

Vaporfuse Smoothing

From Quote To Delivery

Everything You Need In One Easy-to-use Platform

Our AI-powered online quoting tool delivers prices within seconds and makes order tracking and management effortless. With built-in DFM capabilities, it helps identify design errors early, saving you time and ensuring smoother part production.

No Minimum Quantity | AI-Powered DFM Analysis |Online Order Management | Flexible Lead Time & Shipping Options

“IN3DTEC is a wholly trusted partner. They help us develop new products more efficiently and quickly. High-quality products and competitive prices are also why we recommend them to more people.” Luis Ford at Leica Medical Product Design Team

Excellent 4.9 out of 5

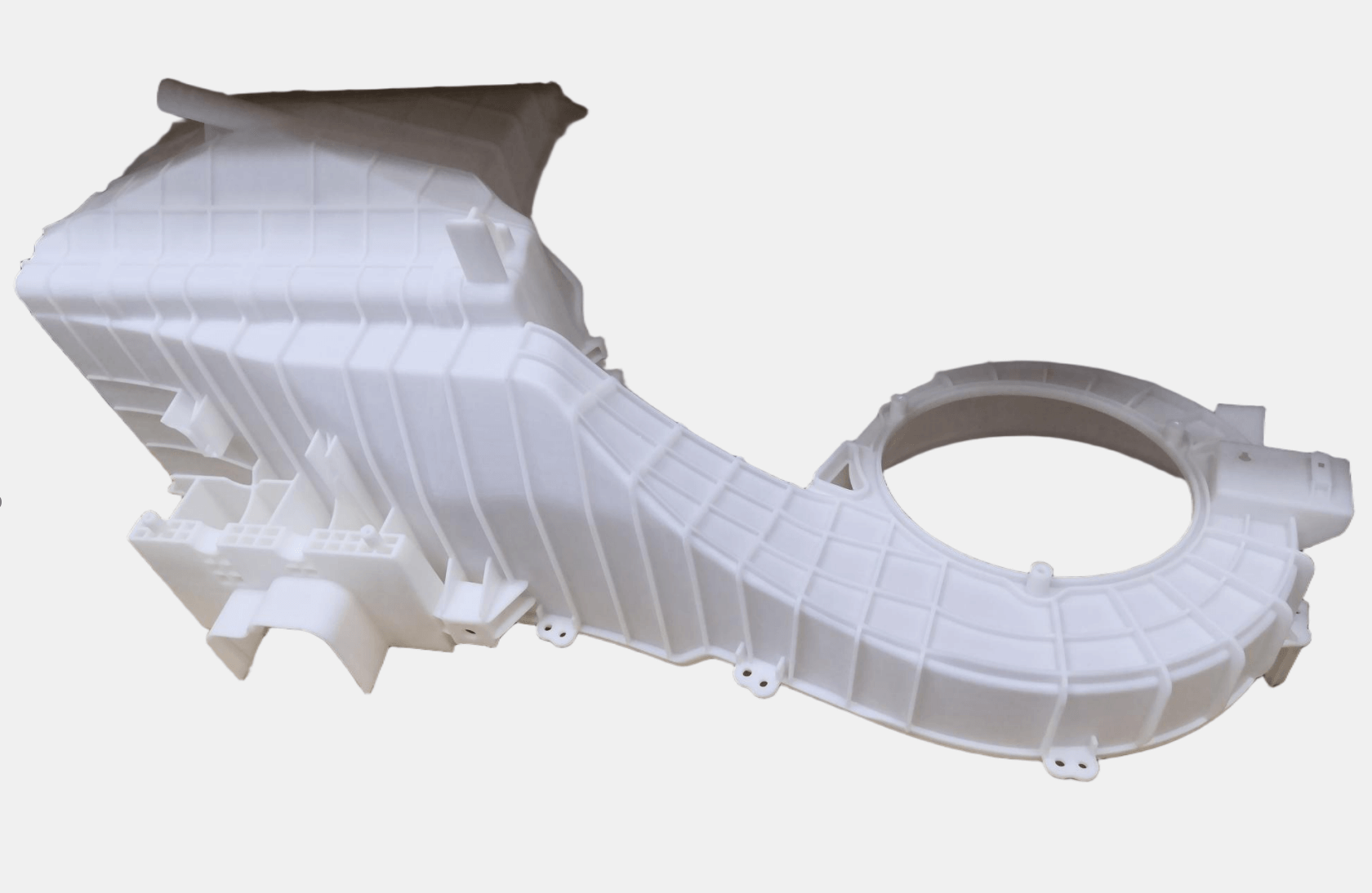

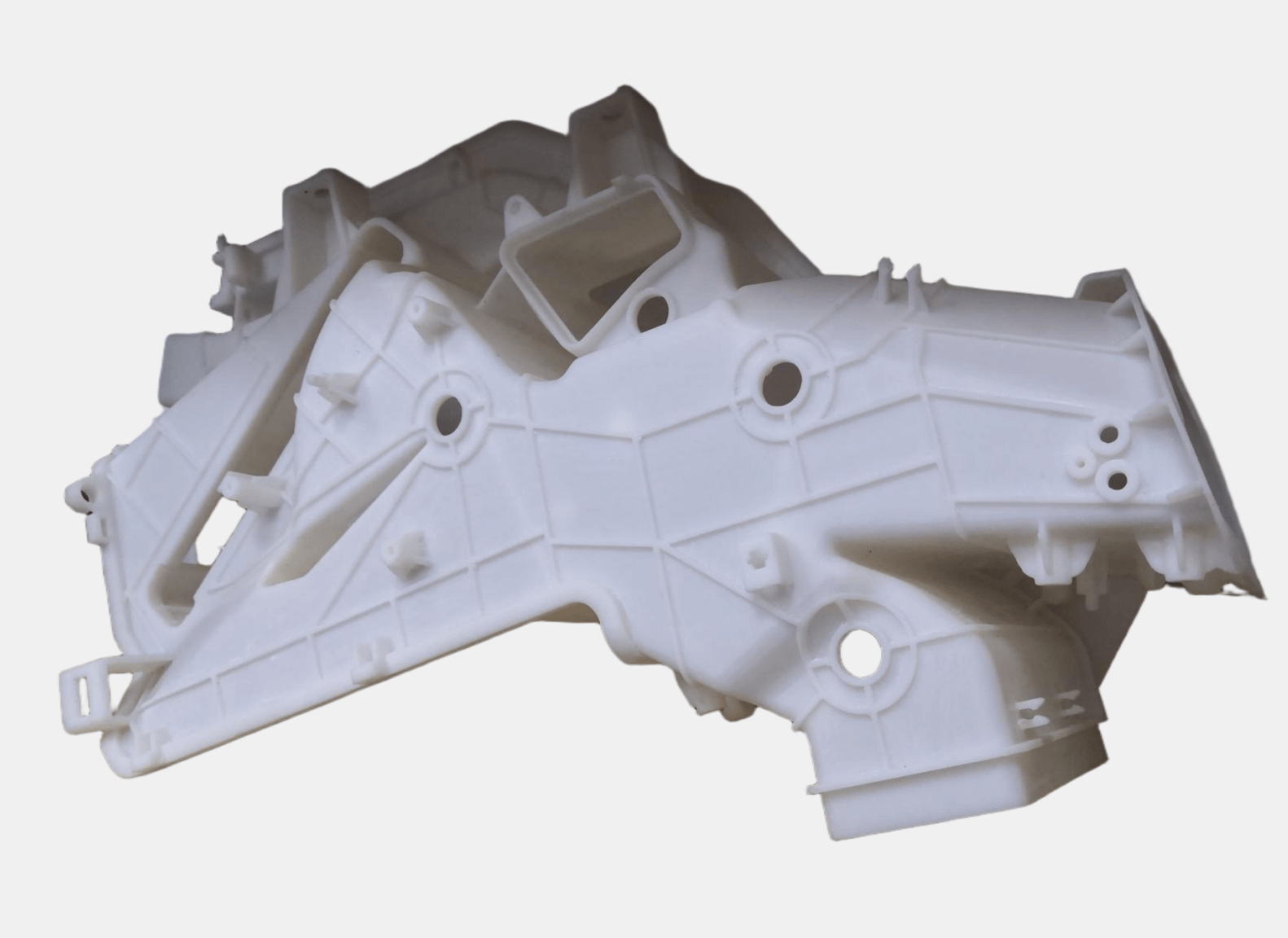

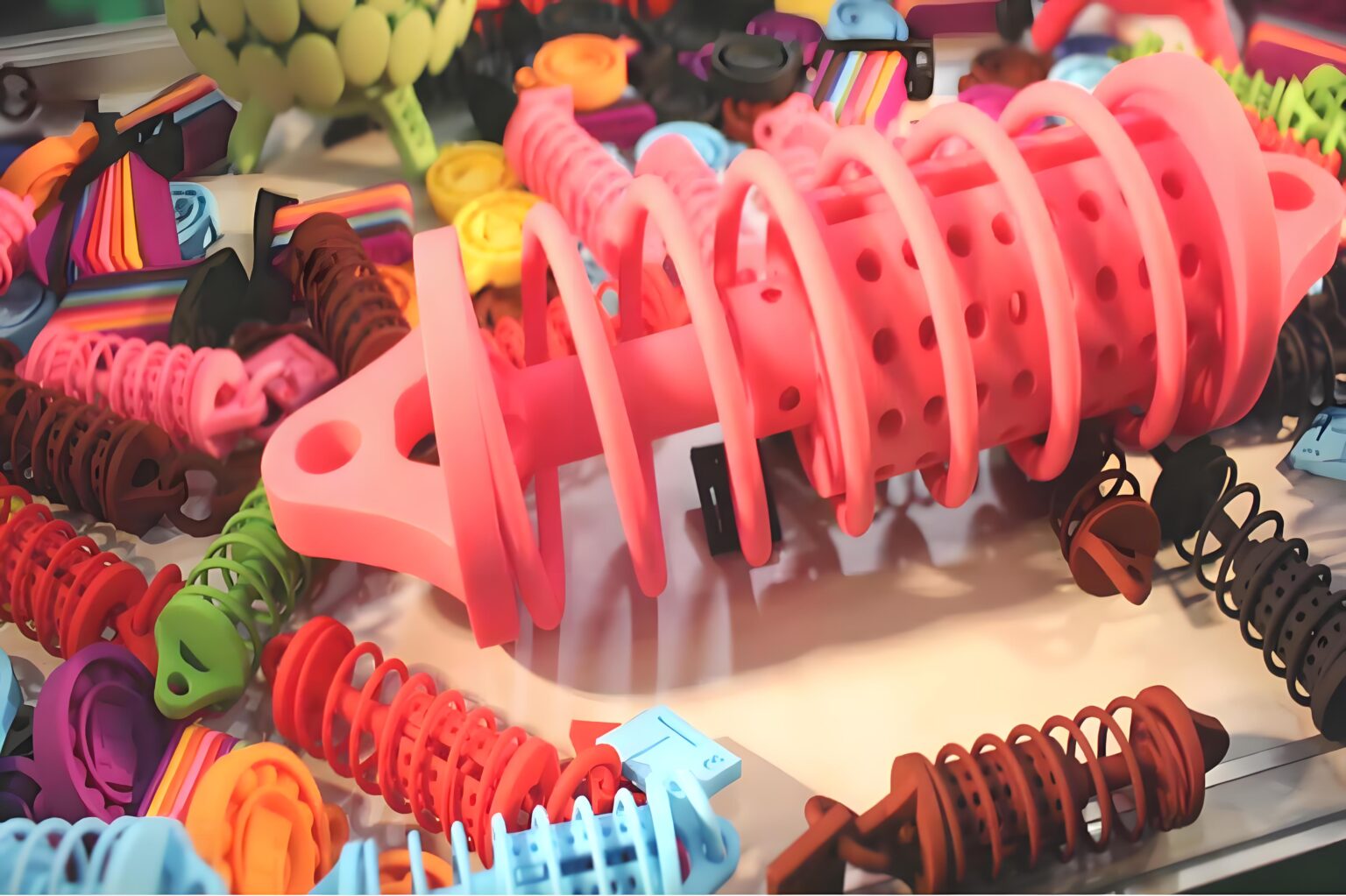

Gallery Of 3D Prints

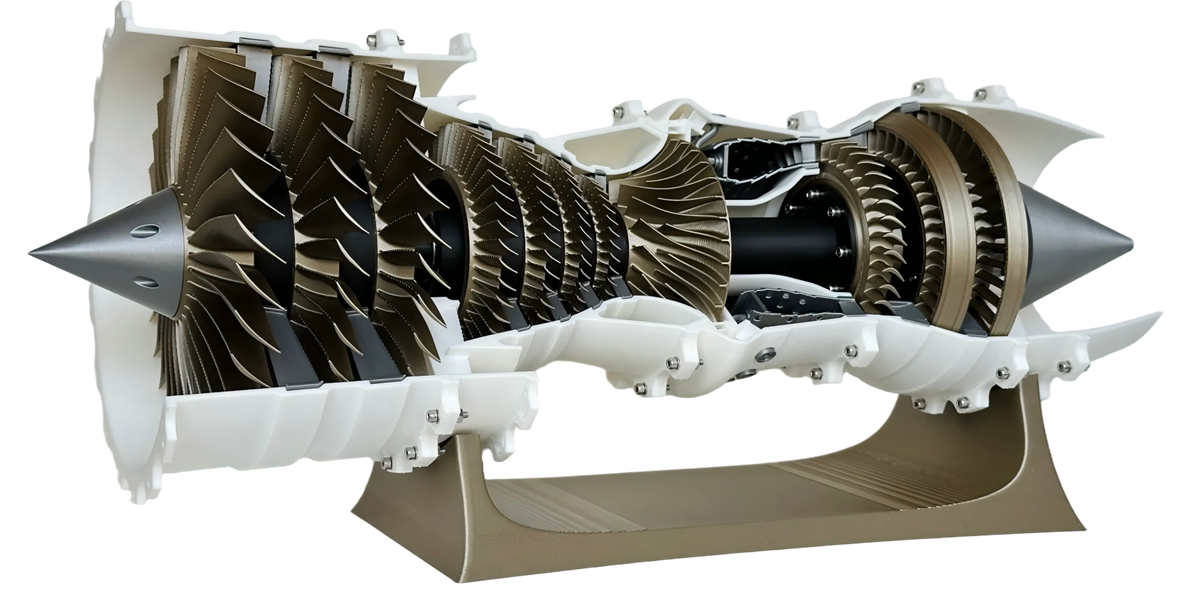

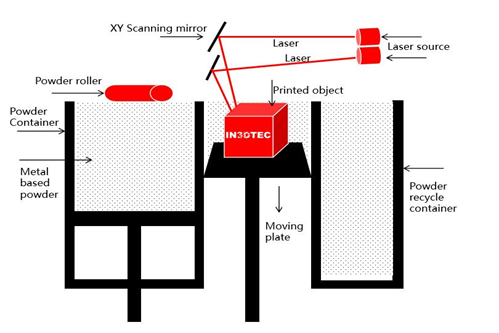

How Does SLA 3D Printing Works

SLA 3D printing begins by forming the support structures, followed by the part itself, using an ultraviolet laser to trace each layer on the surface of a liquid photopolymer resin. After a layer is cured, the build platform lowers and a recoating blade spreads a fresh layer of resin. This process is repeated layer by layer until the part is fully built.

Once printing is complete, the part is removed from the build platform and cleaned in a lab using solvents to eliminate any uncured resin. The support structures are then carefully detached, and the part undergoes an additional UV-curing process to ensure optimal strength and stability. Finally, the component is ready for customized surface finishing.

Download The 3D Printing Guide

Discover proven design rules that help engineers and creators improve performance, save costs, and ensure consistent success in 3D printing projects.

How to Work With

Simply upload your CAD files.

Get real-time pricing and DFM insights within seconds. Or ask for manual design help.

Once your order is placed, we’ll begin production right away, and you can track and manage it anytime from your dashboard.

Partnering with FedEx, DHL, and UPS, we deliver your parts fast and on time, worldwide.

Put your Parts into Production Now

Q & A

A: A: Max. 1700x800x800mm

A: A: 0.5mm

A: A: Nope

A: A: Accuracy: ±0.2% (min ±0.2 mm)

A: Yes, both tinted and fully transparent finishes are available, with painting or polishing if needed.

A: Polyurethane resins simulating ABS, PP, PC, PMMA, Rubber (shore A 30–95), and transparent materials.