Our Reviews

Real Reviews, Real Stories: Hear From Our Customers

- 95.4%of Orders Delivered On-Time and To-Spec

- 18,000+Customers

- 30M+Parts Made

Heliospace

5-Star Rating

Our custom manufacturing partnership with Fictiv helps us from initial design, through to test cycles and gives us a lot more confidence that we can answer customers' needs quickly and win our bids.

Greg Delory, Chief Executive Officer

I worked with in3dtec on a custom support bracket for a mammoth tusk. The bracket took over a year to complete from beginning to end. I had the company..

Jeffry Basinkewitz

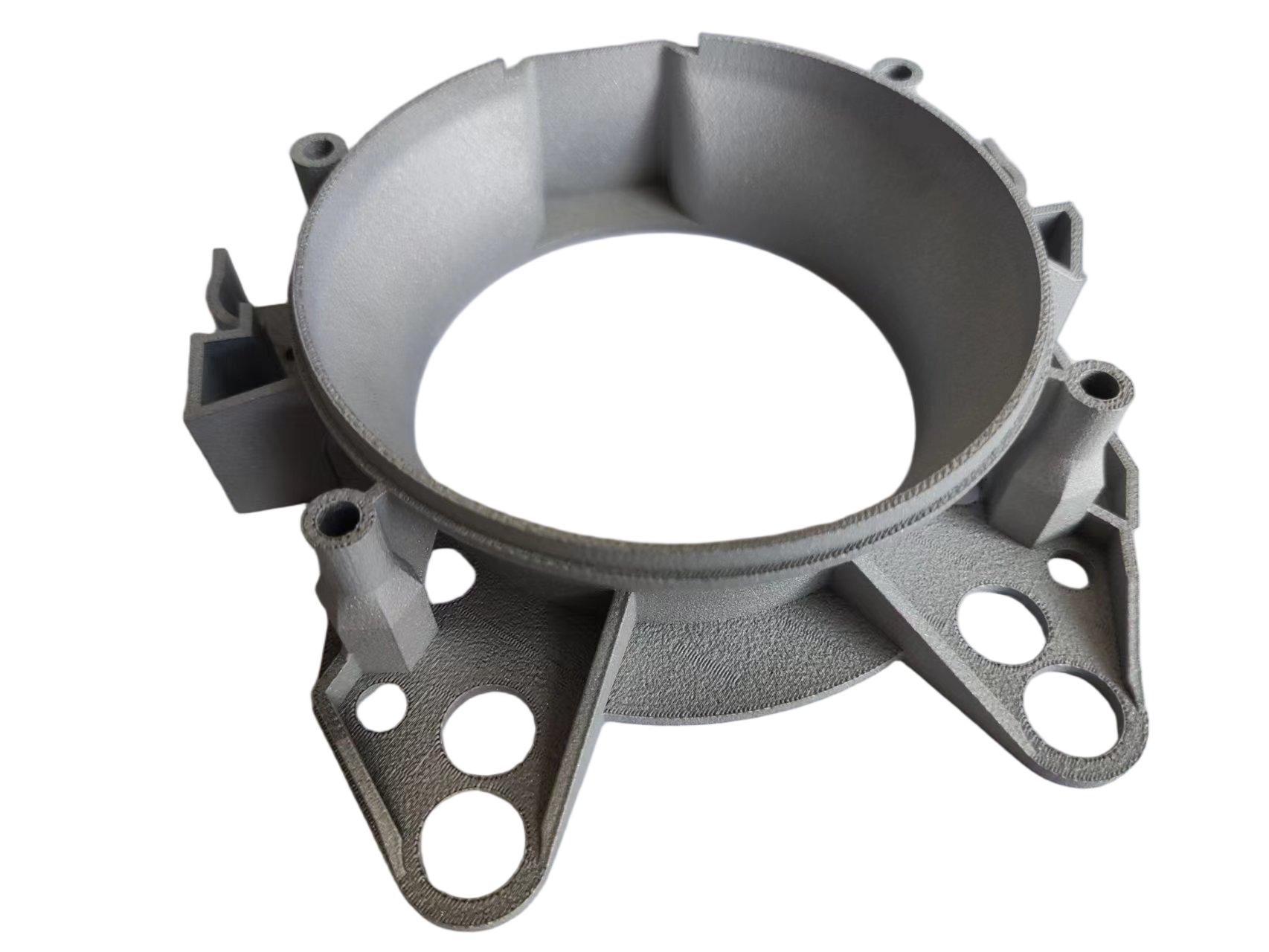

Very nice finish quality on my 3D printed aluminum parts. Dimensional accuracy was perfect and the parts look great on my project.

Luke Ingerman

The parts look great! Be prepared to grind some things down if you need a precise fit, but overall, I’m very happy. The customer service team..

Sean Brosnan

In3Dtec already made a lot of 3D printed parts for me and they are always excellent from quality, delivered quickly for a good price.

A de Wit

We work with them with multiple order and they were up to the specification and professional. recomanded

Amos Rogiani

Everything was printed beautifully and the staff helped us make this possible with their care and attention to detail.

Bes Elgohary

I worked with in3dtec on a custom support bracket for a mammoth tusk. The bracket took over a year to complete from beginning to end. I had the company..

Jeffry Basinkewitz

Very nice finish quality on my 3D printed aluminum parts. Dimensional accuracy was perfect and the parts look great on my project.

Luke Ingerman

I worked with in3dtec on a custom support bracket for a mammoth tusk. The bracket took over a year to complete from beginning to end. I had the company..

Jeffry Basinkewitz

I worked with in3dtec on a custom support bracket for a mammoth tusk. The bracket took over a year to complete from beginning to end. I had the company..

Jeffry Basinkewitz

Content for Plastics - Injection Molding

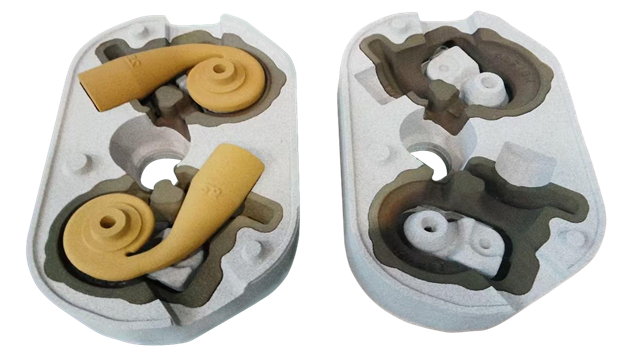

Content for Plastics - Vacuum Casting

Content for Download Center - TDS

Manufacturing Resources

View All

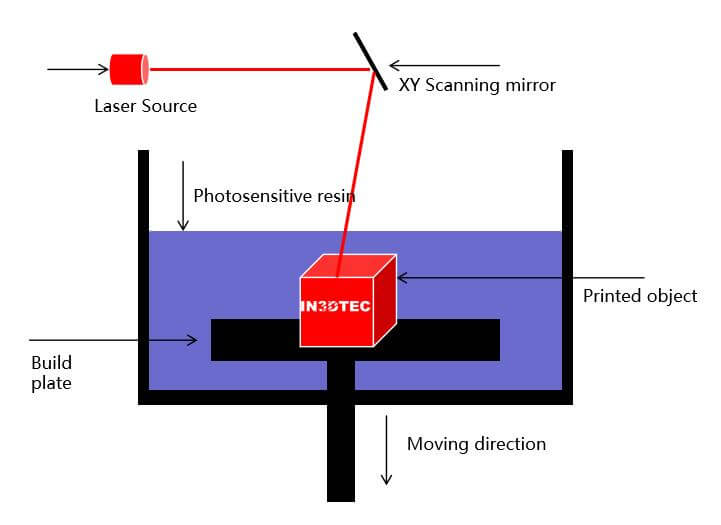

What is SLA 3D Printing? Process, Materials & Benefits

Vacuum Casting, 3D Printing, and Injection Molding are three widely used methods for manufacturing plastic products today. Determining the right choice for your projects requires a breakdown of their differences and an exploration of their respective benefits and drawbacks.

Read More

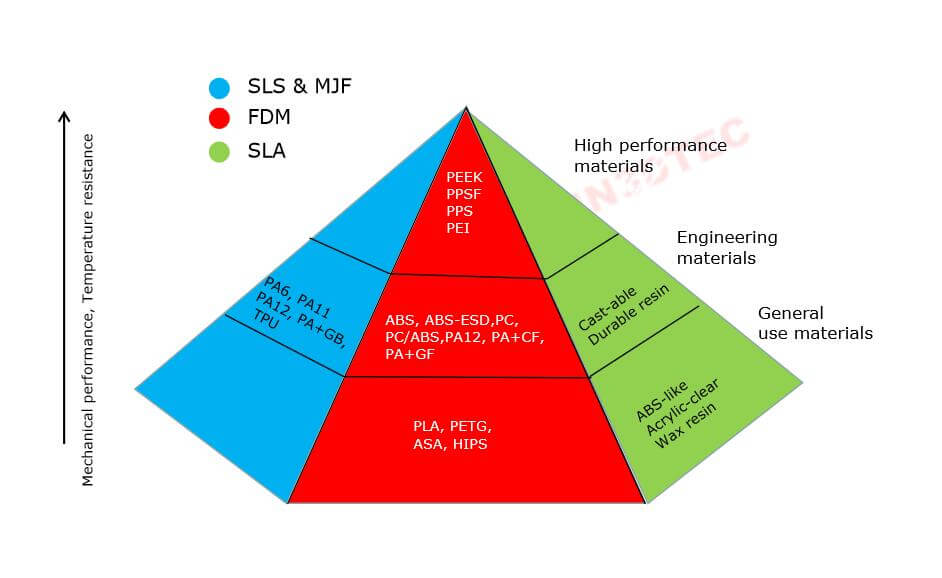

How to choose the right 3d printing material?

Vacuum Casting, 3D Printing, and Injection Molding are three widely used methods for manufacturing plastic products today. Determining the right choice for your projects requires a breakdown of their differences and an exploration of their respective benefits and drawbacks.

Read More

How the Bicycle Industry Benefits from 3D Printing

Vacuum Casting, 3D Printing, and Injection Molding are three widely used methods for manufacturing plastic products today. Determining the right choice for your projects requires a breakdown of their differences and an exploration of their respective benefits and drawbacks.

Read More

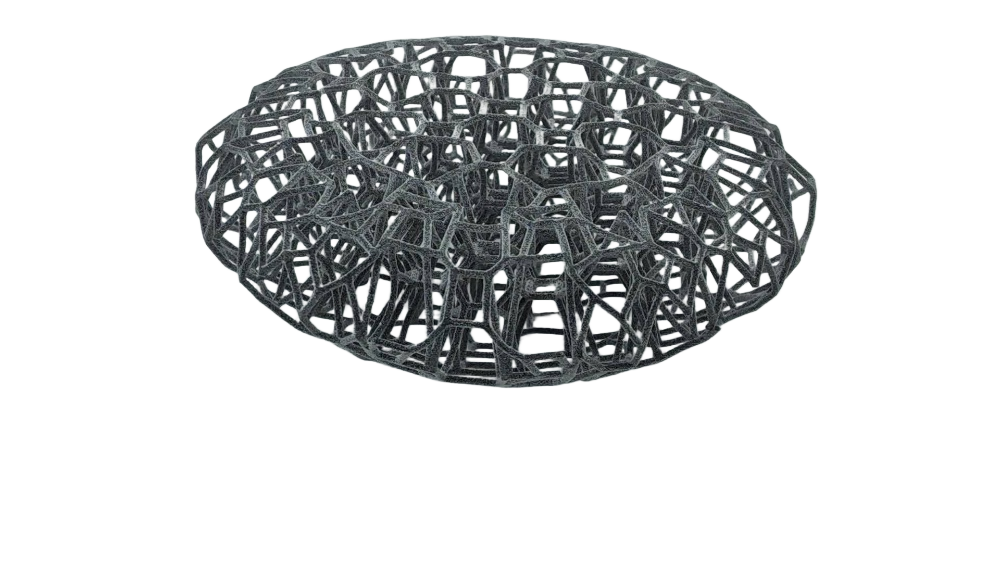

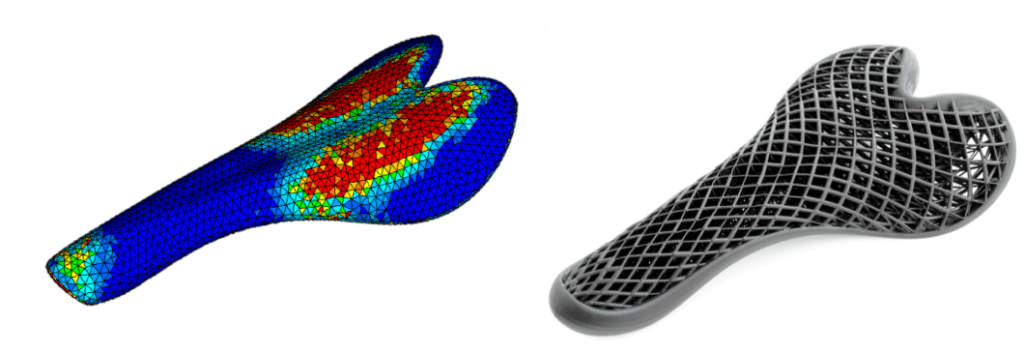

Topology Optimization for 3D Printing

Vacuum Casting, 3D Printing, and Injection Molding are three widely used methods for manufacturing plastic products today. Determining the right choice for your projects requires a breakdown of their differences and an exploration of their respective benefits and drawbacks.

Read More