IN3DTEC Timeline (2014–2024)

-

2014Launched locally, offering metal and high-performance plastic 3D printing and 3D scanning services.

-

2015Core technical team formed; began prototyping with metal/plastic 3D printing, urethane casting, and scanning.

-

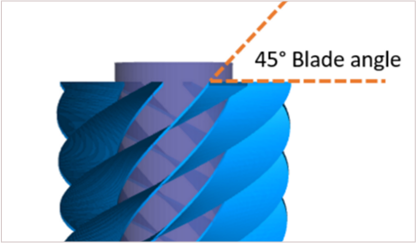

2016Added CNC machining and 5-axis milling for low-volume production.

-

2017Entered overseas markets and became supplier for ABB, Airbus, Danfoss, Leica, Philips, Ford, MIT, and Stanford University.

-

2018Officially established the IN3DTEC global brand for oversea market.

-

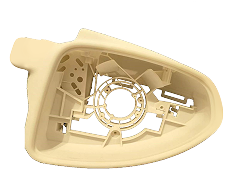

2019Introduced sheet metal and injection molding for on-demand production.

-

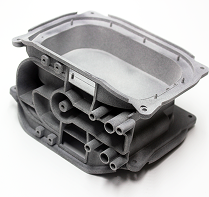

2020Expanded into die casting and custom carbon fiber; grew reach to 70+ countries across Europe, North America, and APAC.

-

2021Broadened 3D printing to ceramic, sand printing & metal casting, soft elastomers, multi-colors, and medical applications; upgraded production and inspection systems.

-

2022Rolled out surface finishing for automotive, aerospace, robotics, medical, and industrial applications; launched Online Quoting System.

-

2023Became a full-scale one-stop shop for prototype to mass production, offering comprehensive manufacturing and finishing services.

-

2024Now serve ¼ of Fortune 500 companies, deliver to 89 countries, support 10,000+ clients with 160+ materials, and offer more than 25+ surface finishe options.

Our Customers

In order to meet different market needs, we expand our offerings to service Aerospace, Automotive, Education, Electricals, Jigs & Fixtures, Medical, Oil & Gas, Transportation, and more. The opinions of our customers serve as the cornerstones for benchmarking our performance which we are committed to continuously improving.

Manufacturing Resources

View All

Vacuum Casting Vs 3D Printing Vs Injection Molding, what's the difference

Vacuum Casting, 3D Printing, and Injection Molding are three widely used methods for manufacturing plastic products today. Determining the right choice for your projects requires a breakdown of their differences and an exploration of their respective benefits and drawbacks.

Read More

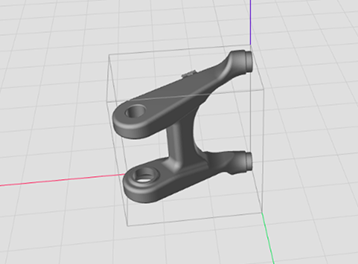

How to design parts for metal 3D Printing?

With the gradual popularization of 3D printing, more and more users will directly consider metal printing when producing products, so how to design a product suitable for metal printing? Is anything we should pay attention to? IN3DTEC will analyze the design skills of metal printing for

Read More

What is vapor Fuse

smoothing?

With the constant growth of Additive Manufacturing and its fields of application, the demand for 3D-printed parts is also increasing.Today, market-ready products manufactured with Powder Bed Fusion technologies such as Selective Laser Sintering (SLS)

Read More

HP MJF Surface Treatment Simplify Explained

This article helps you choose a suitable surface treatment by introducing the post-processing process of MJF 3D printing.There are five common MJF surface treatment processes MJF prints with natural color MJF prints with dyed black...

Read MoreFrom Quote To Delivery

Everything You Need in One Easy-to-use Platform

Our AI-powered online quoting tool delivers prices within seconds and makes order tracking and management effortless. With built-in DFM capabilities, it helps identify design errors early, saving you time and ensuring smoother part production.

No Minimum Quantity

AI-Powered DFM Analysis

Online Order Management

Flexible Lead Time & Shipping Options

Walls are to thin, minimum recommended thickness value is 1.0

Show thin walls

SLM 3D printing

We more focus on it among 3d printing technologies

HP MJF

Superior, Consistent part quality

SLS

Superior, and a wide range of functional plastics

SLA

Extremely detailed copies of real-life objects