Selective Laser Sintering (SLS): The Smart Choice for Prototyping and Low Volume

Selective Laser Sintering (SLS) is one of the most versatile and reliable 3D printing technologies available today. With the ability to produce strong, functional parts without the need for support structures, SLS has become essential in industries like automotive, aerospace, medical, and consumer goods.

Whether you’re prototyping or bridging toward full-scale manufacturing, SLS enables fast iteration, durable results, and highly complex geometries.

What is SLS 3D Printing?

SLS uses a high-powered laser to fuse powdered materials—typically nylon-based polymers—layer by layer into solid parts. Since the unused powder acts as natural support, SLS eliminates the need for additional scaffolding, enabling highly intricate and nested designs.

How Does SLS Work?

- Powder Distribution– A roller spreads a thin layer of powder across the build platform.

- Laser Sintering– A laser selectively fuses powder based on the 3D model’s cross-section.

- Layer-by-Layer Building– The platform lowers and a new layer is applied and sintered.

- Cooling & Post-Processing– After printing, parts are cooled, cleaned, and optionally dyed or smoothed.

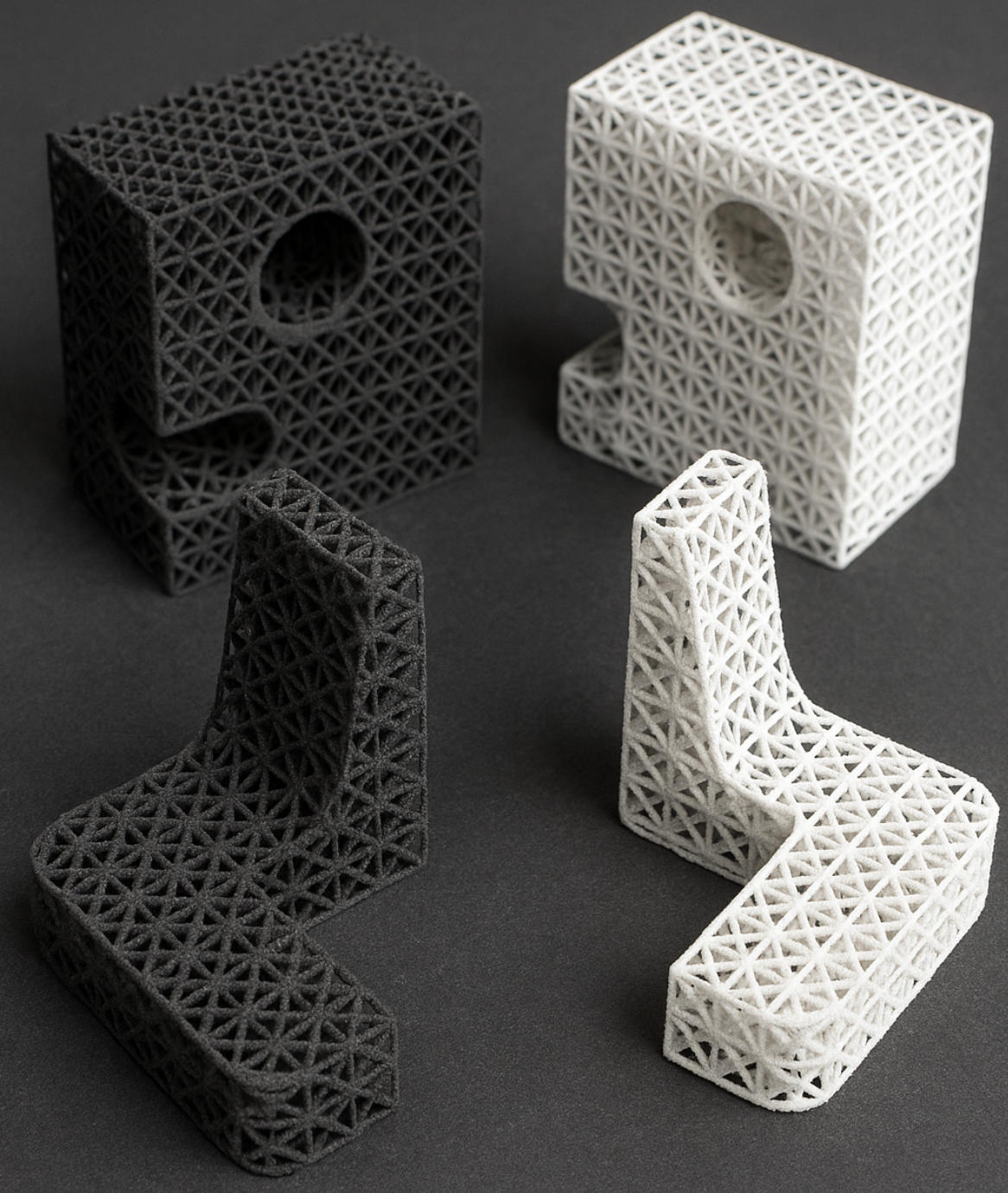

The SLS process selectively fuses powdered material layer by layer using a high-powered laser to build strong and detailed 3D parts.[/caption]

The SLS process selectively fuses powdered material layer by layer using a high-powered laser to build strong and detailed 3D parts.[/caption]

Key Advantages of SLS

Key Advantages of SLS

- No support structuresrequired

- High strength and durabilitysuitable for functional testing and end-use parts

- Excellent geometric complexity

- Reusable material– unused powder is recycled

- Fast productionfor small-to-medium batch quantities

Popular Materials for SLS at IN3DTEC

- PA12 (Nylon 12)– Industry-standard, versatile and strong

- PA12 GF (Glass-filled Nylon)– Enhanced stiffness and dimensional stability

- PA12 CF( Carbon fiber filled nylon) Light weight, strong, durable

- TPU (Thermoplastic Polyurethane)– Flexible, impact-resistant material

- PP (Polypropylene)– Lightweight and chemically resistant for functional parts

- PA11– Biobased alternative with excellent toughness

SLS-printed PA12 component designed as a food-grade equipment enclosure, offering high precision and compliance with food contact standards.[/caption]

SLS-printed PA12 component designed as a food-grade equipment enclosure, offering high precision and compliance with food contact standards.[/caption]

SLS is one of the few 3D printing methods that can process flexible materials like TPU and engineering plastics like PP effectively.

Download the TDS of SLS 3D Printing materials

SLS for Low Volume Production

SLS is often used as a cost-effective alternative to injection molding for low-volume production. It eliminates the high cost and lead time of tooling, making it ideal for:

- Market validation

- Bridge manufacturing

- On-demand spare parts

- Product customization

It is particularly useful for startups, R&D teams, or companies testing functional components before committing to high-volume tooling.

IN3DTEC SLS Capabilities

- Maximum Build Size: 670 x 500 x 450 mm

- Post-processing Options: Sandblasting, dyeing, and VaporFuse smoothingfor improved surface finish

- Batch Production: Multiple parts can be nested and printed in a single run

- Material Range: From rigid PA12 to elastic TPU and lightweight PP

SLS Design Guidelines

To ensure optimal results, follow these SLS design principles:

| Feature | Recommendation |

| Minimum hole diameter | > 0.8 mm |

| Minimum wall thickness | > 0.8 mm |

| Large thin-walled parts | Use reinforcing ribs for stability |

| Surface finish | Slightly grainy (can be improved with VaporFuse smoothing) |

Tip: VaporFuse smoothing provides a sealed, glossy finish that enhances part durability and aesthetics—ideal for consumer-facing or functional products.

Common Applications

- Functional Prototypes

- Customized Medical Devices (e.g., orthotics, surgical guides)

- Automotive Brackets and Ducting

- Wearable Device Housings

- Aerospace Interiors

- Flexible components (using TPU)

SLS vs. Other 3D Printing Technologies

| Feature | SLS | FDM | SLA | |

| Material Type | Nylon powder | Thermoplastic filament | Photopolymer resin | |

| Support Requirement | None | Yes | Yes | |

| Surface Finish | Matte/textured | Layered | Smooth | |

| Functional Use | High | Moderate | Moderate | |

| Lead time at IN3DTEC | 3-4 days | 3-5 days | 2-4 days |

Upload the CAD files to IN3DTEC online quoting tool to quickly understand the cost difference for each technologies and materials.

Final Thoughts

Final Thoughts

Selective Laser Sintering (SLS) combines strength, speed, and flexibility, making it a smart solution for both prototyping and low-volume manufacturing. With IN3DTEC’s advanced SLS capabilities, you can take your ideas from concept to market faster—without sacrificing quality or durability.

Whether you’re printing prototypes, bridge-production parts, or custom-fit components, our expert team and industrial-grade systems are ready to deliver top-tier results.